Globax news

Blog

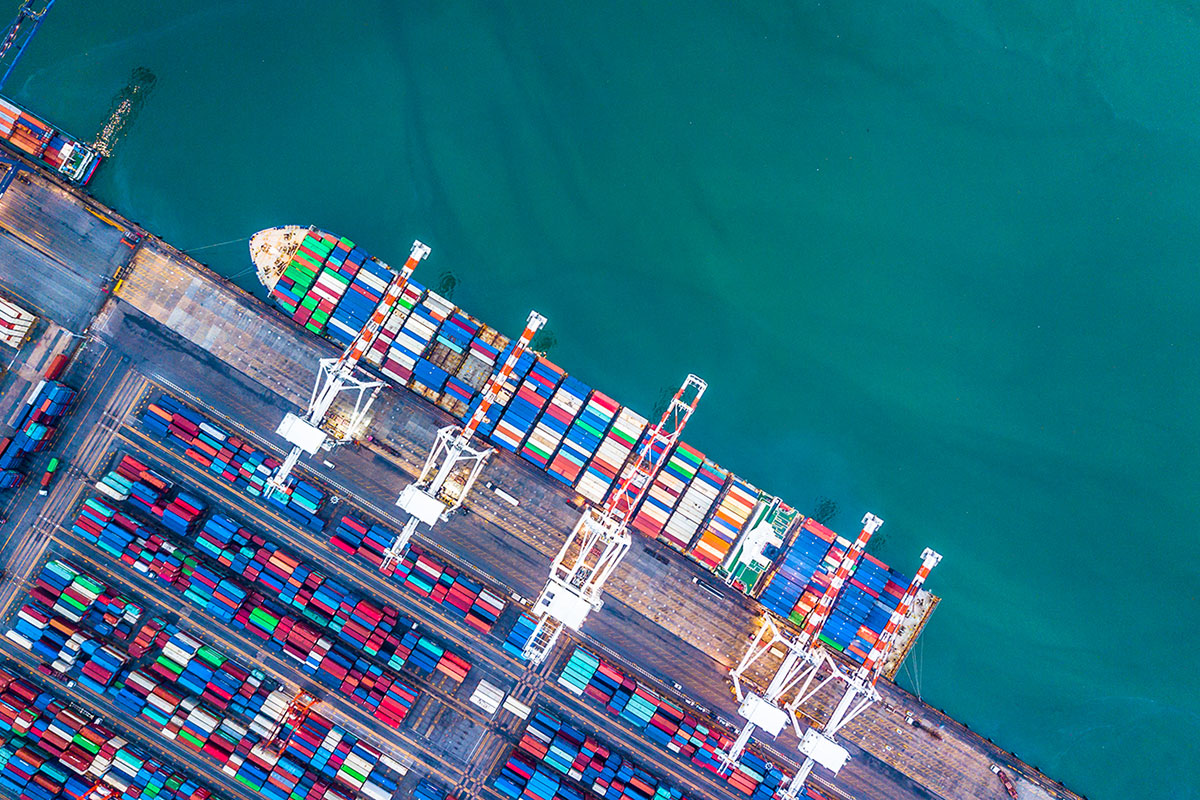

Logistics and Distribution Network in Parallel Export

Logistics Processes in Parallel Export

Parallel export requires an effective logistics and distribution network for successful execution. This process ensures that products reach customers at the right time, in the right place, and in the most efficient manner. Managing the logistics and distribution network in parallel export involves various challenges and key considerations.

1. Logistics Management

Logistics management covers all processes from the point of production to the end user. The main elements of logistics management in parallel export are as follows:

- Transportation: International transportation of products is typically carried out by sea, air, land, or rail. The choice of transportation mode is important in terms of cost, speed, and safety.

- Customs Procedures: Accurate and prompt completion of customs procedures in import and export processes is necessary. Customs duties, import quotas, and other regulations should be considered in this process.

- Storage: Safe storage of products is essential both to optimize costs and to maintain product quality. Strategically positioning storage facilities can reduce logistics costs.

- Inventory Management: Proper management of product stocks prevents overstocking and allows for quick response to demand fluctuations.

2. Distribution Network

The distribution network covers the delivery of products from warehouses to end users or retail points. The main elements of establishing an effective distribution network in parallel export are as follows:

- Distribution Channels: Various distribution channels such as direct sales, retail points, wholesalers, or online platforms can be used. The most suitable distribution channel for the target market should be selected.

- Local Partners: Collaborating with local distribution partners ensures that products reach customers more quickly and effectively. Local partners can better understand market dynamics and customer preferences.

- Last Mile Delivery: The delivery of products to the end consumer is critical for customer satisfaction. Fast and reliable last mile delivery solutions can provide a competitive advantage.

- Technology and Automation: Technologies and automation systems used in logistics and distribution processes enhance operational efficiency and reduce error rates. For example, warehouse management systems (WMS) and transportation management systems (TMS) are highly beneficial in this area.

3. Challenges in Logistics and Distribution

Some challenges that may be encountered in managing the logistics and distribution network in parallel export are:

- Legal and Regulatory Barriers: Legal regulations, customs procedures, and trade restrictions in different countries can complicate logistics processes.

- Cost Management: International transportation, customs duties, and storage costs can increase total logistics costs. Costs need to be managed carefully.

- Supply Chain Disruptions: Interruptions in global supply chains (e.g., natural disasters, political instability) can negatively impact logistics processes.

- Quality Control and Security: Ensuring that products do not get damaged during transportation and storage and that they reach customers safely is essential.

Conclusion

A successful logistics and distribution network in parallel export helps companies gain a competitive advantage and increase customer satisfaction. Careful planning and management of logistics and distribution processes optimize costs while preserving the quality and safety of products. Operational efficiency can be increased, and rapid response to market changes can be achieved by using technology and automation solutions.

As ASR Transit, we work to ensure the proper transportation of your products. We deliver from the manufacturer or supplier to your door with the most suitable route.